How to Design Comfortable Shoes

Good shoes need a combination to create comfortable shoes: last design, upper design, bottom design, material selection, and process design.

1. The impact of the last design on shoe comfort

The design of the last is based on the data of various parts of the foot. From the perspective of shoe design, it is the first priority. The quality of the last design directly affects the beauty and comfort of the finished shoes.

The design of the last is based on the data of various parts of the foot. From the perspective of shoe design, it is the first priority. The quality of the last design directly affects the beauty and comfort of the finished shoes.

The foot has four arches, namely the front and rear transverse arches, and the inner and outer longitudinal arches. During the movement of the foot, the four arches act as springs to reduce the ground recoil. If the forefoot convexity is too large when designing the last, wearing shoes made of this sauce shovel last for a long time will cause the anterior transverse arch ligament to be damaged, lose elasticity, and sink, which will then cause the rear transverse arch and inner longitudinal arch to collapse, forming flat feet. Flat feet can easily cause patients to feel tired and painful during long-term exercise and standing. When designing the forefoot convexity, it is necessary to take the human foot as the basis and design for the front and back arches. The foreleg is based on the natural foreleg of the foot. The height of the foreleg of an adult is generally controlled at 15-18cm. If it is too high, the convexity of the forefoot will be too large. The higher the back foreleg is, the smaller the convexity of the forefoot is, and the smaller the foreleg is. Only in this way can the forefoot contact area be guaranteed, so that the wearer will not sprain his foot.

The metatarsophalangeal joint is one of the main parts that bear the weight of the human body and the labor load, and it is also the key part that bends when walking. Whether the size of the last plantar circumference and the arrangement of the body is reasonable will affect the comfort of wearing and the service life of the shoe. A large plantar circumference and movement of the foot in the shoe are also not good. The height of the back foreleg of the last is generally 20-40cm.

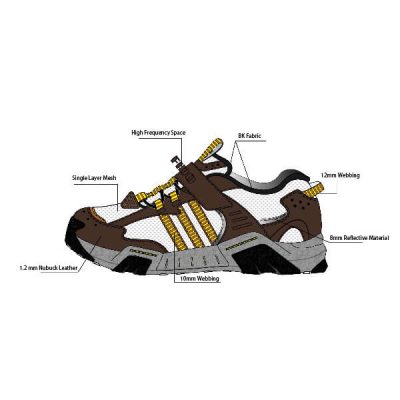

2. Upper sample design

Upper sample design is a link that converts the design into a physical object based on the rules of foot shape, physiological structure, and motor function of the lower limbs, materials, and processes. Through the upper sample design, the design can be smoothly transitioned to the product process processing stage, so as to produce products that meet the design.

Upper sample design is a link that converts the design into a physical object based on the rules of foot shape, physiological structure, and motor function of the lower limbs, materials, and processes. Through the upper sample design, the design can be smoothly transitioned to the product process processing stage, so as to produce products that meet the design.

When designing full-top shoes, the length of the front face of the shoe should be controlled on the last surface – the control point of the mouth position, because when the human body squats or bends the foot, the nasion bend of the foot becomes thicker. The length of the front face generally does not exceed the mouth position, so as to facilitate foot movement and prevent the tongue or shoe ears and other upper parts from rubbing or knocking the foot.

For shoes with a short front face, the heel design should be added to the middle waist and back parts, such as strips or small heels, foot-hugging straps, etc., so that the wearer can walk without effort. It is common in the design of women’s sandals. The narrow strips in the front or the short front upper cannot lift the feet when walking, and it is very laborious to drag the heels. At this time, the heel design should be added to the back.

The height of the middle seam of the back upper Except for high-waisted and tube boots, the height of the middle seam of the back upper of general low-top shoes should be controlled. Especially for leather shoes, because leather shoes have a main heel, too high a back upper will cause foot rubbing and jamming. If it is too low, the shoes will not heel. Its height is controlled above the upper edge of the heel bone, and the range cannot be too large. The reasonable size is set according to experience and process methods.

The height of the inner and outer ankles of the back When designing general low-top shoes, the back curve must be controlled. The theoretical basis is the height of the inner and outer ankle bones of the foot. The height of the lower edge of the center of the ankle bone is obtained according to the law of the foot shape. It can only be lower than this value and cannot be higher. Otherwise, the ankle bone will be stuck and the foot skin will be damaged. And note that the height of the inner and outer ankle bones is not the same. The inner ankle bone is higher than the outer ankle bone. When designing, you can consider that the inner side is 2-3mm higher than the outer side.

The control of the mouth position is set at the bending part of the instep movement. Because the deep and narrow mouth design is easy to tear the upper and inconvenient to put on and take off.

Little toe control point When the broken upper position or the sandal upper strap is designed at the end point of the little toe, if the control is not appropriate, it will cause the little toe to be hit and exposed. It is common for some women’s little toes to drill out of the gap between the sandal straps, and the little toe is easily injured and uncomfortable when walking.

Heel control point Generally controls the position of the columns on both sides of the back of the sandal to improve the carrying capacity of the upper for the heel.

3. The impact of the design of the bottom part on comfort

The design of the bottom part includes the design of the sole, heel, main heel, inner toe, inner sole, etc.

The design of the bottom part includes the design of the sole, heel, main heel, inner toe, inner sole, etc.

The design of the sole should not be too bulky. For shoes worn in winter, a slightly thicker sole is designed to isolate the cold air on the ground and maintain the normal temperature of the feet. Too thick will make the feet feel poorly on the ground, which is easy to cause the center of gravity to deviate and cause sprains. The design of the bottom pattern affects the anti-slip performance of the finished shoe.

The bottom pattern design should resist lateral and longitudinal slippage. The anti-slip effect is good, and the friction between the sole and the ground is increased when walking, and people can walk easily with the help of the reaction force of the ground. On the contrary, people have difficulty walking and are prone to injuries to their feet and bodies. The special structural design allows the air in the shoe to be effectively replaced during exercise, improving comfort.

A reasonably designed heel can make the weight of the human body more reasonably distributed on the support points of various parts of the foot, enhance the stability of the human body, and improve the elasticity of the arch of the foot. The height, size, and shape of the heel affect the comfort of the finished shoe. The height of the heel depends on the height of the back of the shoe last. Pay attention to the coordination of the two when designing or selecting.

The lower edge of the calcaneus is the main force point of the human body’s center of gravity. It is at the center of the heel at the bottom of the human foot. Therefore, the heel seat surface, heel column, and heel surface must penetrate and contain the vertical force between the lower edge of the calcaneus and the ground. The size of the heel seat surface affects the assembly firmness of the heel.

A large heel seat surface has a large contact area with the heel of the sole, and it is not easy to shake when worn; the size of the heel surface affects the ground contact area and plays a role in stabilizing the center of gravity. A heel shape with a small bottom width is not easy to maintain balance during exercise; a heel shape with width but no thickness looks thin and elegant in appearance. If the assembly position is backward, it is easy to make the heel tilt backward when walking, making people feel forward.

When designing the inner toe box, its length cannot exceed the bending part of the foot, otherwise, the bending of the foot is restricted, and there is a hidden danger of getting stuck and grinding the foot.

Due to the physiological characteristics of the foot, the distribution of sweat glands in the human foot is uneven. The density is highest in the sole and metatarsophalangeal joints, and less in the heel and instep. Therefore, attention should be paid to the breathable and sweat-absorbing design of the insole, insole, and lining of the forefoot. The insole design increases softness and breathability. For the insole of sports shoes, the midsole design is added, and elastic materials are used to alleviate the impact between the foot and the ground.

4. The influence of material selection on comfort

The selection of shoe materials is not only about appearance, but also, to a large extent, from the perspective of the hygienic performance of the shoes. Whether the shoes are comfortable or not is related to the microclimate formed in the shoes.

The selection of shoe materials is not only about appearance, but also, to a large extent, from the perspective of the hygienic performance of the shoes. Whether the shoes are comfortable or not is related to the microclimate formed in the shoes.

Natural grain leather and cotton textiles in the upper materials have excellent hygienic properties. Because the materials are breathable, permeable to water vapor, and hygroscopic, they have the premise of not stuffy feet and not covering feet. At this stage, the various synthetic leathers and artificial leathers developed in my country are far inferior to natural leather in terms of hygienic performance. Therefore, when designing, choose appropriate materials according to the style, wearing conditions and environment to improve the wearing comfort of shoes.

Although heavy-finished upper leather and split leather belong to genuine leather shoe materials, their surfaces are covered with coatings, and the pores of natural leather are blocked, so their breathability and water vapor permeability are greatly reduced. For the upper textile materials, attention should be paid to selecting materials with good hygienic properties and comfort, such as breathable, hygroscopic, lightweight, soft, sterilizing, and deodorizing.

The excellent materials of the upper should be used in conjunction with lining, insole, inner toe cap, adhesive and other materials to exert their superior performance. Rico, the shoe material that is closest to the foot, receives steam and sweat from the foot. If the Rico itself does not have the function of breathability and hygroscopicity, the hygienic properties of the fabric will not be exerted.

Good quality insole materials for shoes should be hygroscopic, breathable, have good dimensional stability, anti-flexibility, etc., in order to meet the use requirements, and also provide a comfortable bottom environment for the foot. The performance of the sole material greatly affects the comfort when wearing. The selection is based on the wearing occasion and purpose of the shoe.

For general shoes, the soles designed for use should be light in weight and moderate in hardness. If the hardness is too low, there is no rigidity and the foot is easily strained; if it is too high, the foot will not bend with the foot when walking. Both situations are easy to cause foot fatigue.

5. The impact of production technology on the comfort of finished shoes

The impact of production technology on finished shoes is the impact on finished shoes due to improper or inadequate process operation. Improper or inadequate process operation will affect the appearance, wearing life, and wearing comfort of the shoes.

You May Like

Let WalkNice Help Boost Your Business Today!

Discover the power of Walknice’s tailor-made solutions, designed to unlock your business’s full potential and drive sustainable growth.

Leave A Comment