Footwear Design

Design content: The whole process of conceiving the shape, structure, and production method of footwear, drawing patterns, and drafting relevant technical documents.

Footwear design is based on the physiological structure of the foot, in accordance with the specific technical specifications of shoemaking technology, and follows the principles of practicality, beauty, comfort and economy. It involves disciplines such as anthropology, human anatomy, biomechanics, mathematics, medicine, aesthetics, etc., and must also consider market trends, production and sales, and economic benefits. Footwear design is divided into two parts: last design and shape design.

Last design

The shoe last is the mold of the shoe. In the 1st century BC, the murals of Herculaneum (an ancient city in southwestern Italy) showed the image of a shoemaker pulling the shoe last out of the shoe. In 1961, two Tang Dynasty wooden lasts were unearthed at the site of Niya City in Minfeng County, Xinjiang: one was a men’s last, 24cm long and 8cm wide; the other was a women’s last, 21.5cm long and 7cm wide.

The shoe last is the mold of the shoe. In the 1st century BC, the murals of Herculaneum (an ancient city in southwestern Italy) showed the image of a shoemaker pulling the shoe last out of the shoe. In 1961, two Tang Dynasty wooden lasts were unearthed at the site of Niya City in Minfeng County, Xinjiang: one was a men’s last, 24cm long and 8cm wide; the other was a women’s last, 21.5cm long and 7cm wide.

The earliest shoe last workshop in China was Wang Ji Shoe Last Workshop opened by Wang Arong in Shanghai in 1851. In 1855, the United States began to have machine-made shoe lasts. It was not until the 20th century that the shoe last industry was established. There are three types of shoe lasts: wood, plastic and metal.

The principle of shoe last design is based on the shape of the foot, and is carried out according to the shoe size series standards, the structure, craftsmanship and style of the shoe. Shoe last design includes last sole design and last body design.

Last sole design

The last sole is the basis of shoe last design. It is based on the footprint diagram of a healthy standard foot and the law of foot shape and size, combined with experience and modification. Since the foot expands and contracts when it is moving, still, cold or hot, the length of the last must be greater than the length of the foot. After the sole design is completed, the last body design is carried out on the outline of the sole.

Last body design

That is the design of the cross-section of the last body. During the design, the height and angle of each section are specified according to the size of the last sample and the relevant shoe last size series, and then the contour of the last curve is described using practical experience. In the design of the last, it is necessary to make reasonable arrangements for some key dimensions of the shoe last according to the type of footwear and style.

Mainly:

- ① Forefoot height: the height of the front end point of the last in the basic coordinates;

- ② Heel center padding: the height of the heel center when the required forefoot height is reached after the forefoot convexity of the last touches the ground;

- ③ Back height: the straight-line distance from the back point of the last system opening to the back point of the last;

- ④ Heel center convexity: the degree of convexity of the heel center point of the last relative to the inner and outer width points of the heel center;

- ⑤ Forefoot convexity: the height of the front convexity point of the last relative to the inner and outer width points of the heel center; The degree of convexity of the inner wide point of the first metatarsophalangeal joint and the outer wide point of the fifth metatarsophalangeal joint;

- ⑥ The length of the opening: the straight line length between the front and rear points of the opening;

- ⑦ The thickness of the toe end of the last;

- ⑧ The width of the opening: the width of the middle part of the opening;

- ⑨ The arc of the heel: the degree of convexity between the rear point of the opening of the last body and the rear end of the last;

- ⑩ The rear height of the opening: the vertical height from the rear end of the opening to the ground after the heel center of the last is raised.

Footwear Molding Design

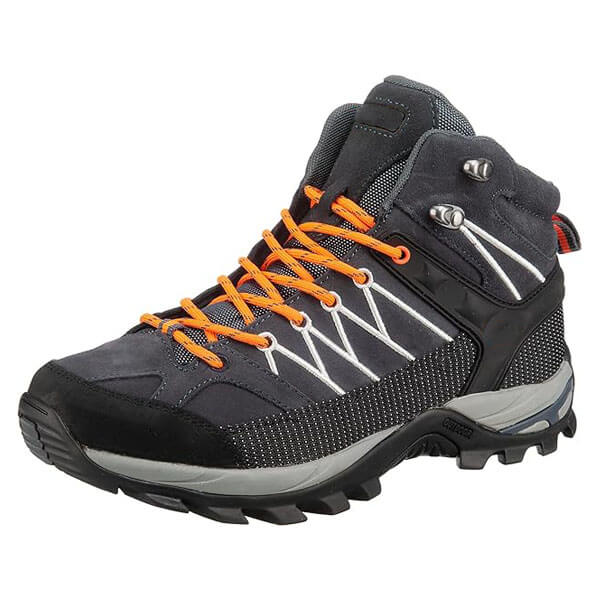

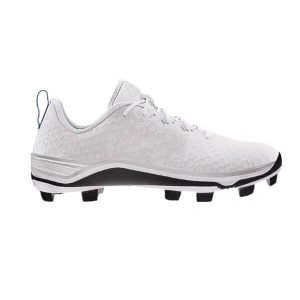

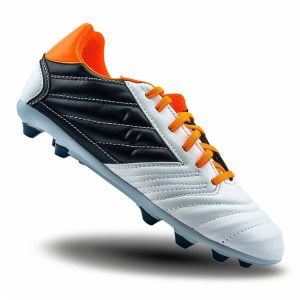

Footwear modeling design is generally divided into 3 parts: preliminary design, upper design, and sole design.

Shoe upper sample design

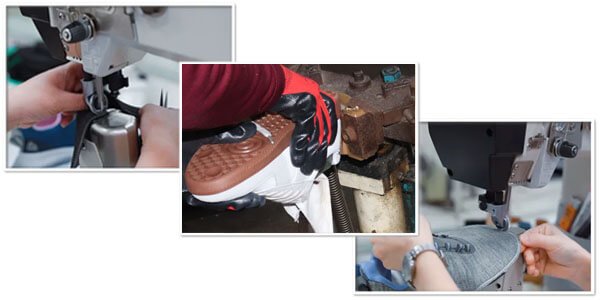

Based on the basic requirements of coordination between shoes and clothes and the basic principles of practicality, beauty, comfort, and economy, the design is conceived and sketched, indicating the composition of raw materials (including types, colors, and performance) and the way of craft structure (sewing, molding, cold gluing, injection molding, etc.) as well as the specifications of the parts.

Based on the basic requirements of coordination between shoes and clothes and the basic principles of practicality, beauty, comfort, and economy, the design is conceived and sketched, indicating the composition of raw materials (including types, colors, and performance) and the way of craft structure (sewing, molding, cold gluing, injection molding, etc.) as well as the specifications of the parts.

Sample design

Two methods are generally used for the design of upper:

- ① Peeling method: use paper, plastic film, and other materials, tightly wrapped in the surface of the last, and then on the last body to depict the gang sample of the various points, and then peeled off the last, after empirical processing, to get the shape of the last and the last face in line with the planar gang sample plate.

- ② Drawing method: Adopt the geometric drawing method of triangular approximation to transform the complex surface of the last into the exhibition plane, and design the gang sample directly in the exhibition plane. To make the sample of the spreading plane match the shape of the last’s surface, it is necessary to deal with the stilt degree of the sample, i.e. to raise or lower the stilt point of the head of the sample.

Sole design

The design of the sole refers to the design of various parts attached to the sole of shoes, such as the inner sole (the sole that touches the bottom of the foot), the outer sole (the sole that touches the ground), the strip (the strip sewn or glued on the edge of the sole at the lower edge of the upper), the inner head (the shaping part that is clamped between the upper and the upper), and the design of the main heel (the shaping part that is clamped between the upper and the upper) of shoes, etc.

The design of the sole refers to the design of various parts attached to the sole of shoes, such as the inner sole (the sole that touches the bottom of the foot), the outer sole (the sole that touches the ground), the strip (the strip sewn or glued on the edge of the sole at the lower edge of the upper), the inner head (the shaping part that is clamped between the upper and the upper), and the design of the main heel (the shaping part that is clamped between the upper and the upper) of shoes, etc.

The design of the bottom parts is related to the shape of the shoes and is also associated with the design of the lasts, which is the design of the lasts.

The design of the bottom piece is related to the overall shape of the shoes, especially the heel of women’s shoes.

The sole pattern of sports shoes should be designed according to the biomechanical principle combined with the material of the sole, to enhance the performance of the sole such as anti-shock, anti-skid, and wear-resistant.

Introduction of Microelectronic Technology into the Footwear-Making Industry

In the early 70s, microelectronic technology was introduced into the shoe industry. Firstly, it was used in the sample-releasing machine. Soon, the electronic computer-aided design (CAD) system was gradually applied in some developed countries, which made the design of shoes change by leaps and bounds.

In the early 70s, microelectronic technology was introduced into the shoe industry. Firstly, it was used in the sample-releasing machine. Soon, the electronic computer-aided design (CAD) system was gradually applied in some developed countries, which made the design of shoes change by leaps and bounds.

The new product GM-510 microprocessor system launched by American Gerber Kamska in 1985 reflects the functional status and technical level of the contemporary CAD shoe design system, which enables the designers to do the following:

- ①Collect and digitize the shoe samples, expanded and reduced drawings, and other information materials;

- ② Observe the shape of shoes and modify them through the color images on the computer terminal screen;

- ③ Automatically expand and shrink the sample;

- ④ Drawing part samples, production drawings, and color pictures;

- ⑤Store information and accumulate shoe styles.

The company is developing another CAD system called the apex, in addition to the above functions, in which the three-dimensional digital converter can display the three-dimensional model of the last on the screen, and the designers can draw the shoe samples on the model of the last directly and can modify the shoe samples on the screen, move, rotate, zoom, etc. The CAD system can enable the design of shoes to be modified.

The CAD system can make the speed of shoe design much higher, the shoe samples more accurate, and the design process more flexible and free.

You May Like

Let WalkNice Help Boost Your Business Today!

Discover the power of Walknice’s tailor-made solutions, designed to unlock your business’s full potential and drive sustainable growth.

Leave A Comment